This article was originally published on the Gazette.com

Like many medalists, Michelle Dusserre Farrell’s path to the podium began in front of a TV. She wasn’t quite 4 years old but still remembers how it felt to watch the “Sparrow from Minsk,” Olga Korbut, dazzle the world and reset the bar for competitive gymnastics at the 1972 Munich Olympics.

“It got me excited about the sport, then it was my mom putting me into a gymnastics class, and then four years later watching Nadia (Comaneci) score her first perfect 10,” said Farrell, who went on to earn a spot alongside Mary Lou Retton, and a silver medal for Team USA, at the 1984 Summer Games in Los Angeles, when she was just 15.

“Watching Nadia score a 10 (in 1976), which had never been done before, it was almost like it gave me permission to dream,” Farrell said. “If she could score a 10, and that couldn’t be done, then what else was possible?”

What sets a medalist apart from the rest of the best is measured in heartbeats and fractions of fractions. What connects all Olympic and Paralympic alumni to one another — and makes their stories resonate so powerfully with the rest of us — isn’t so easily quantified.

That ineffable something is what makes the Games more than just competition, and the U.S. Olympic Museum and Hall of Fame more than just a showcase for sports history, said museum CEO Christopher Liedel.

“What we want to do in this museum sort of captures a little bit of that essence … that, how do we inspire?” said Liedel at a November talk hosted by Colorado Springs’ Downtown Partnership. “How visitors take in that content is a big factor, and that goes back to museum design.”

Most older museums aren’t oriented along a fluid storyline, said Liedel, who joined the project a month before its groundbreaking last June, after high-profile jobs with the Smithsonian Institution and National Geographic magazine.

It’s, “doors open, you walk in … and people scatter,” he said.

Such a dated and unstructured model wouldn’t work for Olympic City’s eponymous gallery, which called for an inside space that not only would augment a $20 million high-tech and artifact-rich narrative of the Games — and make the experience relevant, and accessible, for each of the estimated 400,000 annual visitors — but, on the outside, tell the story in its skin and bones.

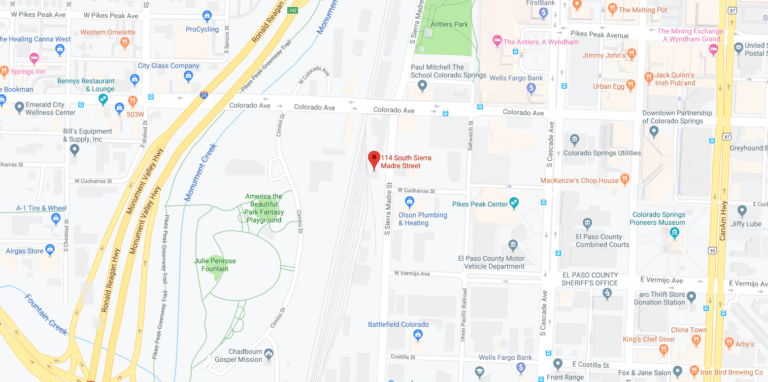

The $50 million building, now in the final phase of construction on a 1.7-acre tract at Vermijo Avenue and Sierra Madre Street, began as a cocktail napkin-style burst of inspiration by design architect Liz Diller.

The lead designer at New York City’s Diller Scofidio + Renfro sketched out a vision of twisting angles and swooping lines that were meant to capture the motion of a discus thrower midfeat at the base of the New World Olympus — Pikes Peak.

“One of the things I tell people, what I think is the real magic of this is that Liz Diller sketched this in just a few minutes,” said Peter Maiurro, the museum’s interim chief operating officer. “And instead of trying to compete with or overpower the natural landscape, she truly embraced it with the design.”

Translating Diller’s concept into a 60,000-square-foot structure of steel, glass and aluminum, corkscrewing down around a soaring three-story atrium, presented a challenge for the ages for the Springs’ GE Johnson Construction Company.

“The look was really a lot of the building — is a big part of the building,” said project manager, John McCorkle. “The complexity of it drove us to really think outside the box on how we coordinate, more so than we typically coordinate on construction projects.”

The design required “15 independent concrete slab-on-metal deck elevations, scaling just four stories of construction with no two planes running parallel for long,” crowed a recent piece in STRUCTURE magazine, which likened the building’s assembly to an “exceptionally intricate puzzle” with structural tolerances “ultra-tight (and) even less forgiving” as work progresses, which isn’t the case with most builds.

The design also called for a “skin” of almost 10,000 diamond shaped aluminum panels, to give the building an appearance of perpetual movement.

“It’s really cool how the sun hits it in different ways. In the morning is my favorite,” said McCorkle in January.

Before that facing could go up, though, the steel structure had to be fully erected and excruciatingly mapped, by lasers. Each diamond panel is unique, crafted in Minnesota and trucked into the Springs, where it’s slotted into a designated spot on the angled roof, over a layer of painted-on, aqua-hued waterproofing. The margin for error is, effectively, nil.

That means no shims. No caulk.

“I joke about this, because it’s been a little anticlimactic for us, because we put so much effort into the coordination part,” McCorkle said. “A lot of times in construction, we’ll tell the framer, ‘Hey, I need you to hold to this dimension,’ and it’s kind of 50-50 if that happens or not. Ultimately it means you have issues, and something doesn’t align.”

In this case, though, “we couldn’t afford to do this.”

“Every one of these panels has a inch joint between this panel and the next panel, and every one of them has to be perfect,” McCorkle said.

“If you can imagine doing a puzzle with all these pieces, and something not aligning … for it to work we had to be absolutely sure that the subcontractor before him and the subcontractor before them, that everything was done and it was totally coordinated, with everybody’s input, to come up with the right process.”

“This mock-up took us 10 months to build and was a huge milestone in the project,” McCorkle said. “Once this got approved, it allowed us to release everything for fabrication.”

Inside the building, the personally curated tour that begins on the third floor and spirals down through a series of exhibits travels through spaces designed to maximize more than just information delivery.

They wanted emotion, a “sensory experience,” said former Olympian Farrell, who’s now working on the museum’s content committee to promote the project and gather “valuable input” from Olympic and Paralympic athletes.

The build up to the Parade of Nations exhibit is physically designed to amplify the moment’s actual, and spiritual, acoustics. Farrell said that ceremony was one most Olympic and Paralympic alumni agree was their most powerful experience of the Games.

The goal was to recreate that feeling, as closely as possible. Which meant using the space to build anticipation.

“When I walked into the opening ceremony in ’84 — to a coliseum full of 100,000 people — there was a big long tunnel. It was dark, but as you got closer to the stadium you could see the light. You could see the crowd. You could hear it,” Farrell said.

“It was an amazing sort of visceral experience that we talked a lot about when they were doing the design, so that part was really kind of an important piece of the build up. We’re hoping too that when athletes come to visit and they go through, they say we got it right. And we’re working really hard to make sure that happens.”

As part of her job with the museum, Farrell sometimes leads tours of the building as construction wraps up.

In May, she took her daughter, Abby, a Paralympic hopeful who plays wheelchair basketball for the University of Illinois, where she will be a junior in the fall.

Abby was one of the athletes Chris Liedel spoke with, when trying to make sure the museum’s design not only met, but exceeded, legal requirements for visitors with disabilities.

Liedel, she said, had questions about whether “someone in a wheelchair would be able to fully experience everything; would they be able to reach everything?”

Abby said she’s excited to be part of the project as a contributor, extended member of the Olympic family, through her mom and just a local witness.

“I was in town last summer and got to drive by every day when it was still kind of a skeleton almost,” said Abby, who interned with U.S. Figure Skating last summer and is headed to USA Triathlon this break.

“Now that I’ve been gone 8 months and I’m back, it’s like, wow. This is cool to be able to see it more complete and I can’t wait to see it when it’s done.”